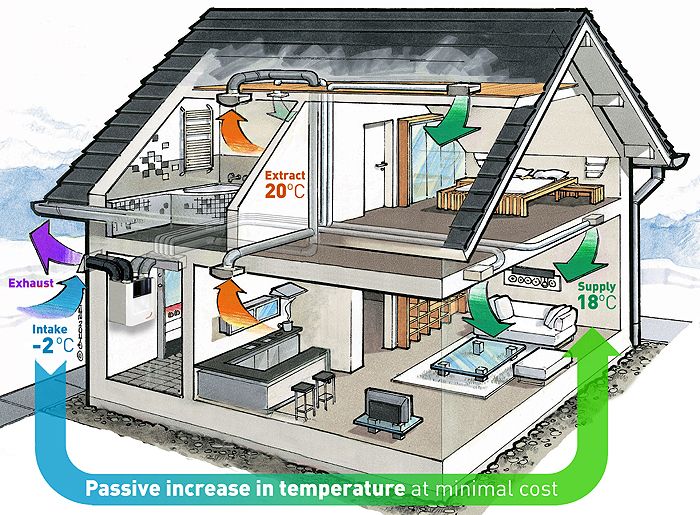

Some recent experiences—personally and professionally—have got me thinking about how ambitions and plans (no matter how big and exciting) tend to rely, at the end of the day, on some pretty basic nuts-and-bolts stuff. Take energy efficient buildings as an example. It is easy to get excited about architectural designs, fancy features, and even an impressive list of a property’s environmental credentials. We all like Grand Designs. But the reality is that the success of these buildings depends entirely on the reliability and effectiveness of some pretty unglamorous machinery (an MVHR or a heat pump) and some pretty unexciting tasks (eg. sealing holes with tape).

This is why it is so important that processes such as the installation and commissioning of units (heat pumps and MVHR) and air tightness checks are done correctly and also why good communication among different people working on a project matters.

What can go wrong with MVHR and Heat Pump installation?

An MVHR unit may not be installed correctly—bad duct design, or incorrect duct types (“flexi” duct is often used, even though industry guidance is to use a maximum of 1.3m of flexi ducts on MVHR installations. Personally, we never use any of flexi duct)—or it may be badly commissioned and incorrectly balanced. Bad design and installation choices can mean that airflow may not reach all the areas it should (leading to damp or condensation or varying levels of CO2 through the house). A system wrongly installed is also likely to need more maintenance, with more wear on fans and other system components: an unnecessary expense that also gives the systems a bad name.

Similarly, heat pumps need to be properly installed if they are going to be produce the optimal coeffecient of performance (4 or 5). If a heat pump is oversized for the property this can lead to a decrease in coefficient of performance (sadly, average coefficient of performance for buildings in UK is in the mid 2s). Knowledge of good design for low flow temperatures is really critical. Heat Geek is at the forefront of pushing out really good information and training but these have not yet reached the wider installer community.

The difficulty for a homeowner is how to know who to go for . . . How do you know an installer will need to know what they need to know? Here’s a few tips:

For ventilation, check if the installer is BPEC accredited (BPEC) https://bpec.org.uk

Check if the installer has a record of good installations they have done.

For heat pumps, check out Heat Geek for a map of installers. https://www.heatgeek.com/find-a-heat-geek/

And for heat pumps, check in with the installer on some key questions:

What flow temperature are they designing for?

What steps are they taking to make sure the heat pump will run for a long time?

Are they configuring weather compensation to help optimise performance?

These are good indicators about the ability of the engineer to design an efficient heat pump system